How Are Custom Promotional Products Printed?

When shopping for promotional products for your business, organization, or event, customization is key. Adding your business name, logo, or contact information to items not only gives people a valuable gift but also keeps your company in their minds.

As you look through our inventory, you’ll see different ways to print your information on promotional products. It’s useful to know what these methods are and which products they work best on. Some options are perfect for clothing but not suitable for custom mugs or water bottles. In fact, some methods simply don’t work on certain items. For example, trying to engrave a logo on a golf towel isn’t a good idea.

To help you understand this better, we’ve created a guide on the most popular ways to imprint custom promotional products. Read on to become an imprinting expert!

1. Screen Printing

Screen printing, also known as silk screening, is one of the most popular methods for printing custom promotional products. It involves creating a stencil (or screen) and using it to apply layers of ink on the product’s surface. This method is ideal for larger quantities due to its efficiency and cost-effectiveness.

This method is often used on fabrics, but it can also be used on wood, metal, plastic, and glass. The main drawback of screen printing is that it isn’t good for very detailed designs. While it is possible to create multicolor images with screen printing, this increases both the cost and production time.

Process:

- A screen is created with the desired design.

- Ink is pressed through the screen onto the product.

- The product is then dried to set the ink.

Best For: Custom T-shirts, tote bags, and other fabric items.

2. Digital Printing

Digital printing is a modern method that allows for full-color designs and intricate details. This process involves using digital printers to apply ink directly onto the product’s surface. It’s suitable for small runs and products requiring high-resolution images.

Process:

- The design is created digitally and uploaded to a computer.

- The printer applies the ink directly to the product.

- The product is then dried or cured, depending on the material.

Best For: Custom mugs, phone cases, and promotional posters.

3. Embroidery

Embroidery involves stitching designs onto fabric products, giving a high-quality and durable finish. This method is perfect for adding a professional touch to promotional apparel and accessories.Embroidery for custom products uses a large machine to automatically sew designs onto multiple pieces at once. This allows us to add your logo or message to items like polo shirts, hats, and many other types of promotional apparel.

Process:

- The design is digitized into a format that the embroidery machine can read.

- The machine stitches the design onto the product using colored threads.

- Excess threads are trimmed, and the product is inspected for quality.

Best For: Polo shirts, caps, and custom jackets.

4. Pad Printing

Pad printing is used to transfer 2D images onto 3D objects. This method is versatile and can print on a variety of surfaces, including plastic, glass, and metal.Pad printing involves creating a large rubber pad with the design and stamping it onto the object. We often use this process for uniquely shaped items like stress balls, plastic boxes, fly swatters, and many others.

Process:

- A silicone pad picks up ink from an etched plate.

- The pad then transfers the ink onto the product.

- The product is dried to set the ink.

Best For: Pens, keychains, and promotional stress balls.

5. Heat Transfer

Heat transfer printing involves using heat and pressure to transfer images from a special paper onto the product. This method is excellent for full-color designs and photographs.

Process:

- The design is printed onto transfer paper.

- The paper is placed on the product, and heat and pressure are applied.

- The design transfers from the paper to the product.

Best For: T-shirts, custom bags, and hats.

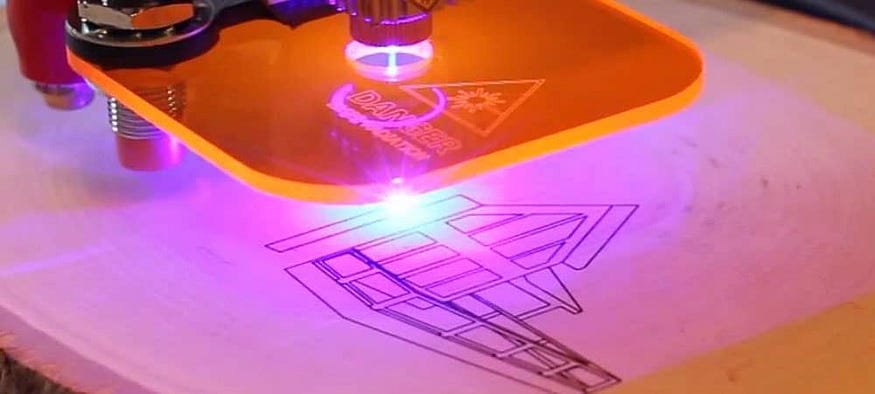

6. Laser Engraving

Laser engraving is a precise method that uses a laser to etch designs into the product’s surface. This technique creates a permanent and sophisticated look, perfect for high-end promotional items.

Process:

- The design is programmed into the laser engraving machine.

- The laser etches the design onto the product by removing the surface material.

- The product is cleaned and polished if necessary.

Best For: Metal pens, wooden items, and glass awards.

Which is the best method for imprinting promotional products?

Choosing the right printing method depends on two main factors: your budget and the item you’re printing on. A third factor to think about is your design and the colors or textures that will work best.

We’ve already mentioned that certain materials work better with specific printing methods. It’s also important to know that more detailed methods can cost more, especially for large orders. If your business has a limited budget or needs a lot of items, it might be best to choose a simpler printing style.

Conclusion

Choosing the right printing method for your custom promotional products depends on the material of the product, the complexity of the design, and your budget. Each method has its unique advantages, ensuring that your promotional items will stand out and leave a memorable impression.

By understanding these printing techniques, you can better appreciate the art and effort that goes into creating high-quality promotional products. Whether you’re looking to print a simple logo on a pen or a detailed full-color design on a t-shirt, there’s a perfect method out there for your needs.

Ready to create your custom promotional products? Visit OptamarkGraphics.com to explore our wide range of printing options and get started today!

FAQs

1. What is the most durable printing method for fabric products?

Embroidery is known for its durability and professional finish on fabric products.

2. Can I print photographs on promotional products?

Yes, digital printing and heat transfer methods are ideal for printing high-resolution images and photographs.

3. Is screen printing suitable for small quantities?

Screen printing is generally more cost-effective for larger quantities, but it can be used for smaller runs if necessary.

4. What products are best for laser engraving?

Laser engraving works well on metal, wood, and glass items, providing a sophisticated and permanent design.

5. How do I choose the right printing method for my promotional product?

Consider the material of the product, the complexity of the design, and your budget to select the most suitable printing method.

.jpg)

Comments

Post a Comment